Quasi Static Testing Systems

Computer controlled servo-

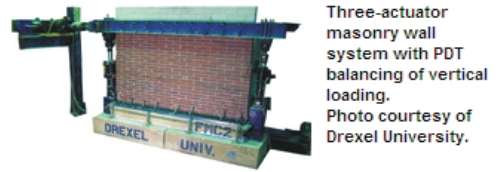

During PST the controller internally computes the theoretical inertial forces that would exist in the true dynamic event such as an earthquake. Hence, PDT can slowly expose a structure to the forces, strains, and displacements that would actually occur during a dynamic event. The advantage over a shake table is the ability to test much larger structures, without requiring large and more expensive hydraulic power systems, shake tables, and actuators with high flow servo valves.

Components of a typical ANCO quasi static testing system include:

- Structures laboratory with strong floor and walls with attachment inserts.

- Multiple actuators with static force rating of 100 kN -

1000 kN. Stroke from +/- 100 mm to +/- 400 mm. Peak velocity of 1 cm/s - 10 cm/s. - Vane type bridge load cells with 150% force measurement overload capacity.

- Magnetostrictive coaxial displacement transducers.

- Zero maintenance PTFE swivels or steel-

on- steel lubricated swivels on base and piston, with client specified bolt pattern. Swivels have +/- 100 degree/+/- 8 degree capacity. - Hydraulic power supplies rated for fatigue operation and 15-

180 GPM. - Hydraulic power supply with capacity of 30-

300 GPM (110- 1100 L/min) at 3,000 psi (21 MPa). - Hydraulic hoses to place the actuators up to 30 m from the strong wall or strong floor local manifolds (with quick release connectors).

- 5-

15 GPM two- stage servo valves (option for larger valves). - Frequency response 0-

20 Hz. - PC-

based digital control system (ANIPC and TRIDENT) with up to 8 actuators control and acquire up to 128 channels of data. - Additional strain or displacement measurement transducers, as required.